SUPPLY CHAIN TRANSPARENCY & RESPONSIBILITY

We design and sell our clothing ourselves. Production is handled by specialized suppliers. The clothing supply chain has many stages, from the cotton farmer to the factory where your favourite item is sewn. To work more sustainably and have clarity about our impact, it's important we know our chain. Our goal is a supply chain with 100 % transparency up to and including the yarns by 2025. In 2024 we were at 97 %.

What have we done so far to achieve this? We began by mapping our most direct suppliers and each year go deeper into the chain; we are getting to know our indirect partners, such as laundries and fabric producers. The figure below shows each step in the supply chain and what percentage of our suppliers have already provided us information about factories at those stages.

As you can see, we already have significant insight into our chain. But we’re not there yet. That’s why we continuously work to increase our insight. Step one is knowing where our products are made. That allows us to verify production locations and work with suppliers on improvements.

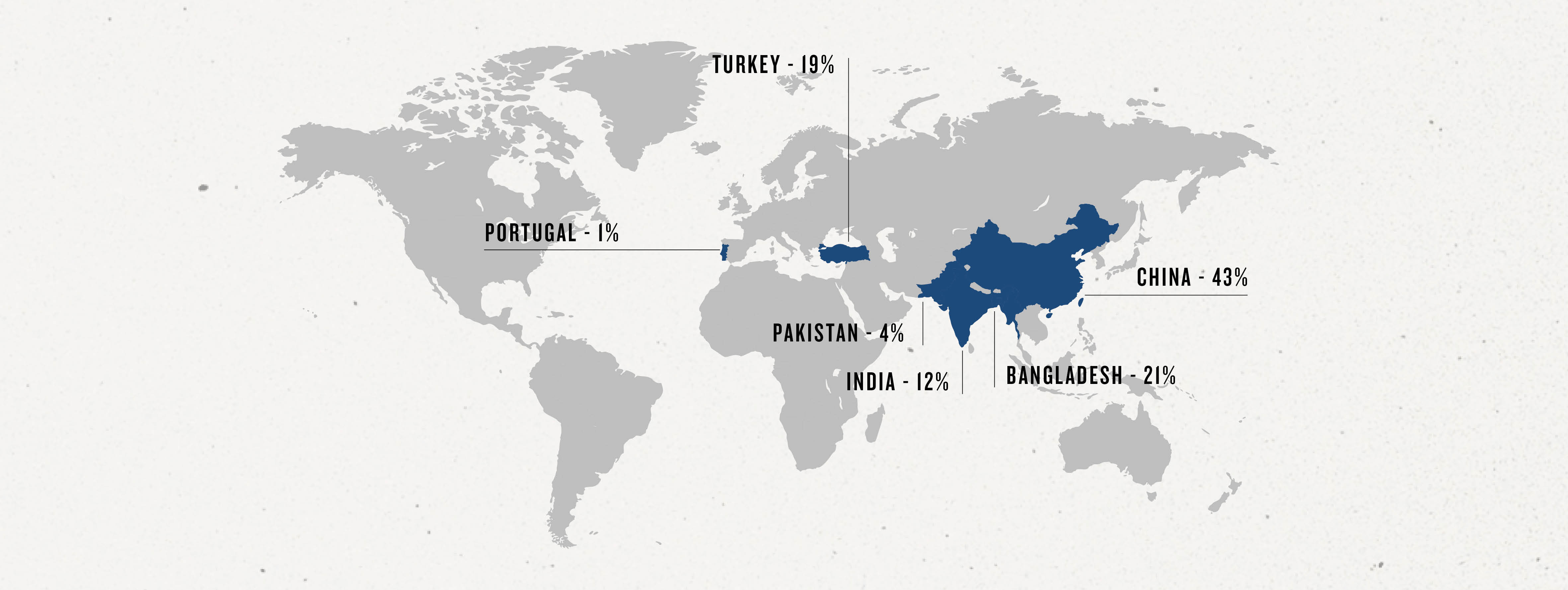

So where are our products made?*

* based on purchase value in 2024

Supplier contracts

America Today aims to build fair and long-term relationships with suppliers. We want to support suppliers in creating working environments that respect human rights and the environment. We know our buying practices can influence risks in the chain. That’s why we have established procurement principles. Our purchasing team strives to apply these to prevent risks and support suppliers. Our standards and values are captured in our Supplier Declaration for Social and Environmental Sustainability. This agreement outlines our requirements and guidelines for suppliers on topics such as transparency, protecting worker rights and safety, prohibited chemicals, and preferred or disallowed materials. Our procurement principles and the amfori BSCI code of conduct are included in this document. All of our direct suppliers have signed this declaration.

Factory oversight

We visit all our sewing ateliers in risk countries at least once a year to see working conditions and product quality with our own eyes. Our local procurement and quality teams perform inspections concerning labor conditions, safety and product quality. We also monitor our suppliers’ conditions via independent audits, mainly through the amfori Business Social Compliance Initiative (BSCI), which we joined in 2013. By collaborating with others in the industry, we can pool our strengths to achieve more. Amfori BSCI is an independent organisation aiming to improve working conditions across global production chains. An independent assessor audits the entire factory, interviews workers, and reviews administrative records. The aim is to identify areas for improvement. BSCI audits take place twice a year, with one or more follow-up audits as needed. For more information, visit amfori.

We aim to help suppliers make improvements by providing constructive feedback on their improvement plans. Suppliers also receive BSCI training, and we collaborate on projects around specific themes (see for example ‘Respecting human rights’). This approach helps suppliers gradually improve labor conditions. Currently, all sewing ateliers we work with in risk countries are covered by BSCI or another recognised independent social audit system. Our requirement is at least a C-level score in the BSCI system or an equivalent result.

Monitoring wet processing factories

In addition to factory inspections, we want to assess deeper levels in the supply chain. We start with factories where our products are washed, dyed, or printed. These require specific knowledge as such processes use lots of energy, water and chemicals, which may impact people and the environment. In 2021, our local procurement teams received training on the risks of these processes and the questions they should ask suppliers to drive improvements. By 2025 we aim for all wash, dye and print factories to be audited by our local colleagues or an independent audit.